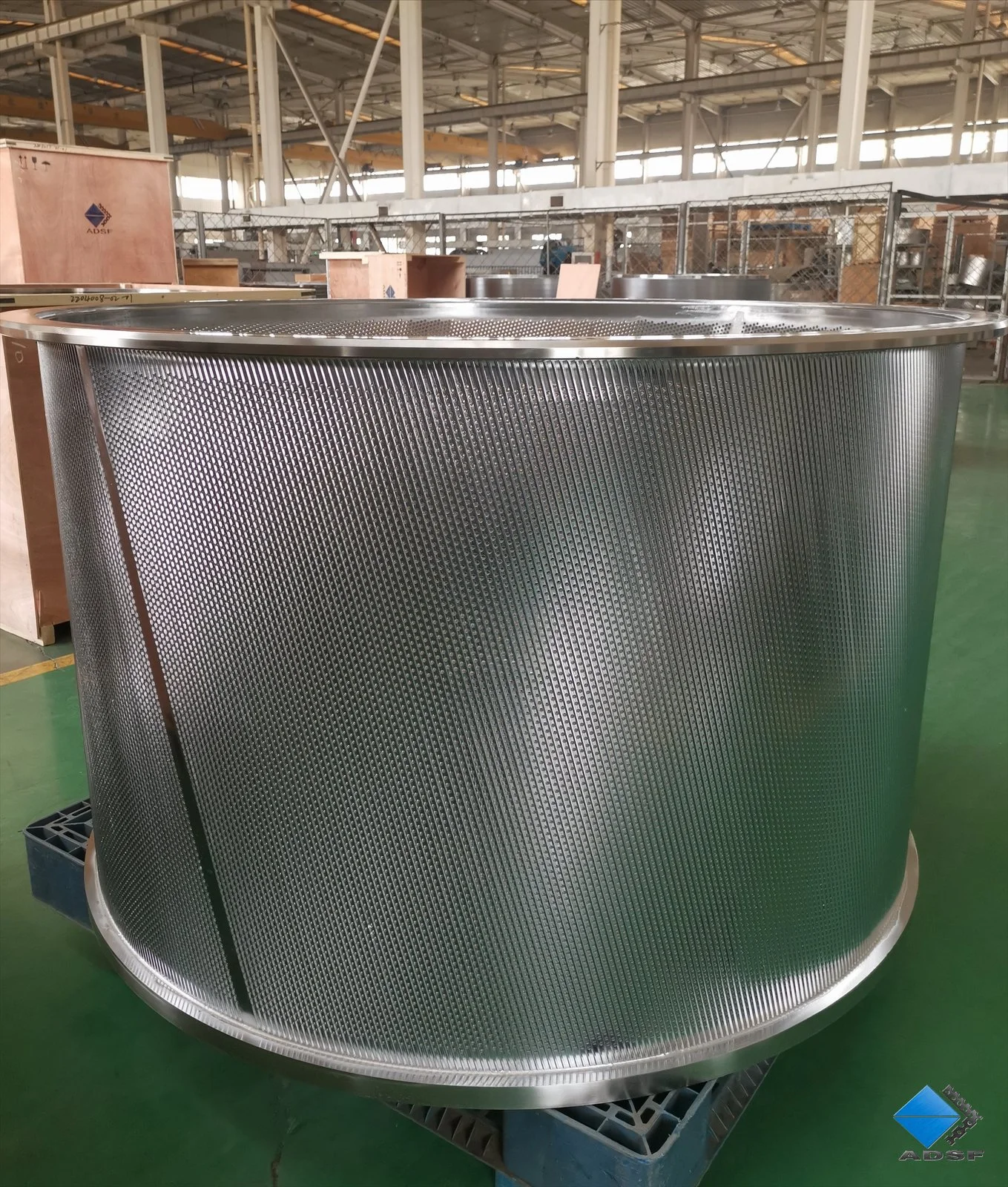

ADSF wedge wire slotted screen basket without welding. The advancement of manufacturing technology enhances surface smooth and improves basket strength and durability. The seamless design is suitable for high consistencies and high rotor speeds.

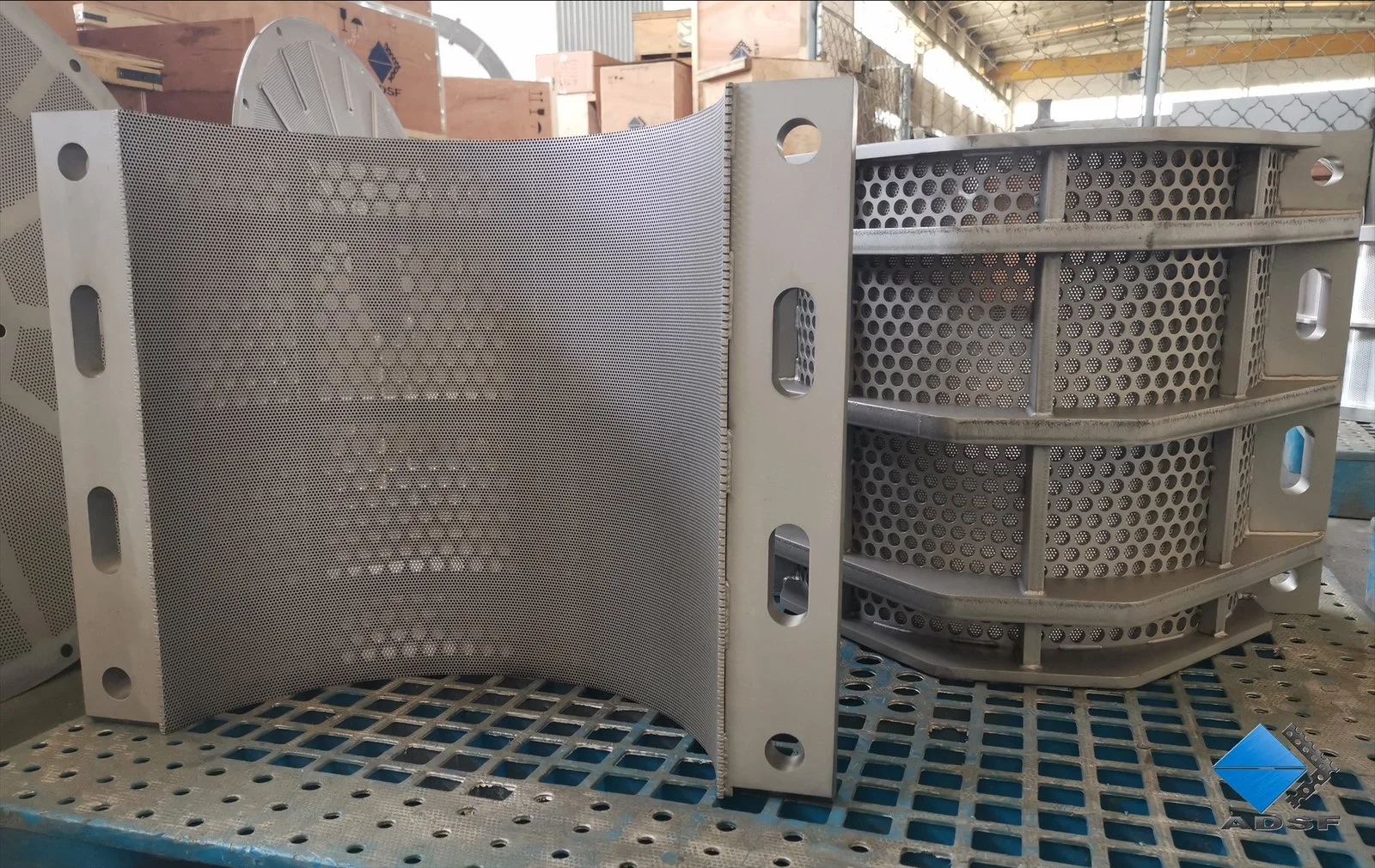

ADSF screw press screen basket with feeding port

ADSF Screw Press Screen Basket is mainly used for dewatering of pulp and recycled fiber application. It can separate impurities and defiberize stock, regularly improve the productive efficiency, and reduce energy consumption.

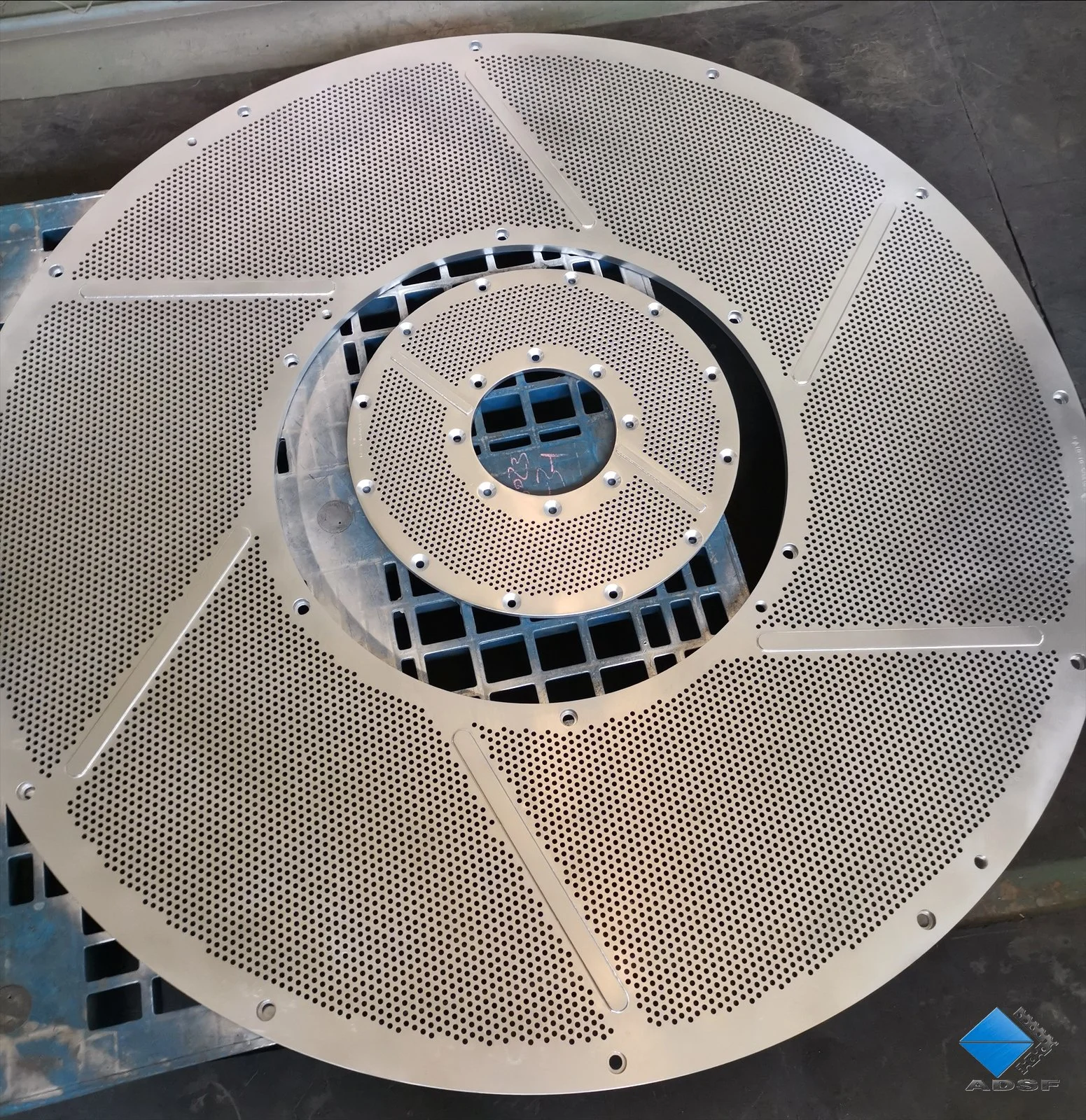

ADSF Coater Filter Screen Basket

Coater Filter screen basket is typically used in chemical treatments added to paper machines. Our product has higher fitting precision, compared with the polygonal shape products from other competitors. We provide wide range of V-wires and support rods to suit customers needs.

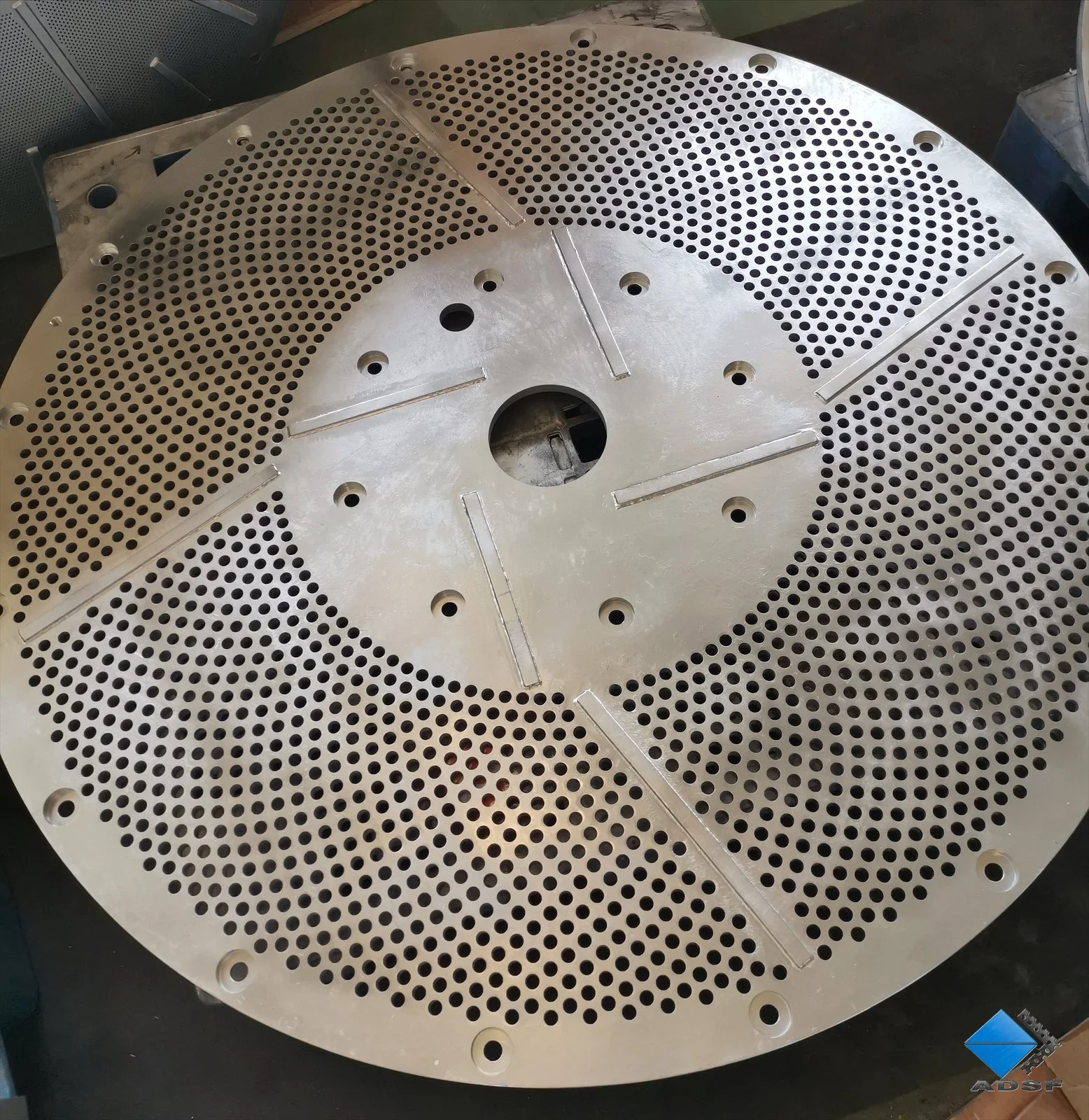

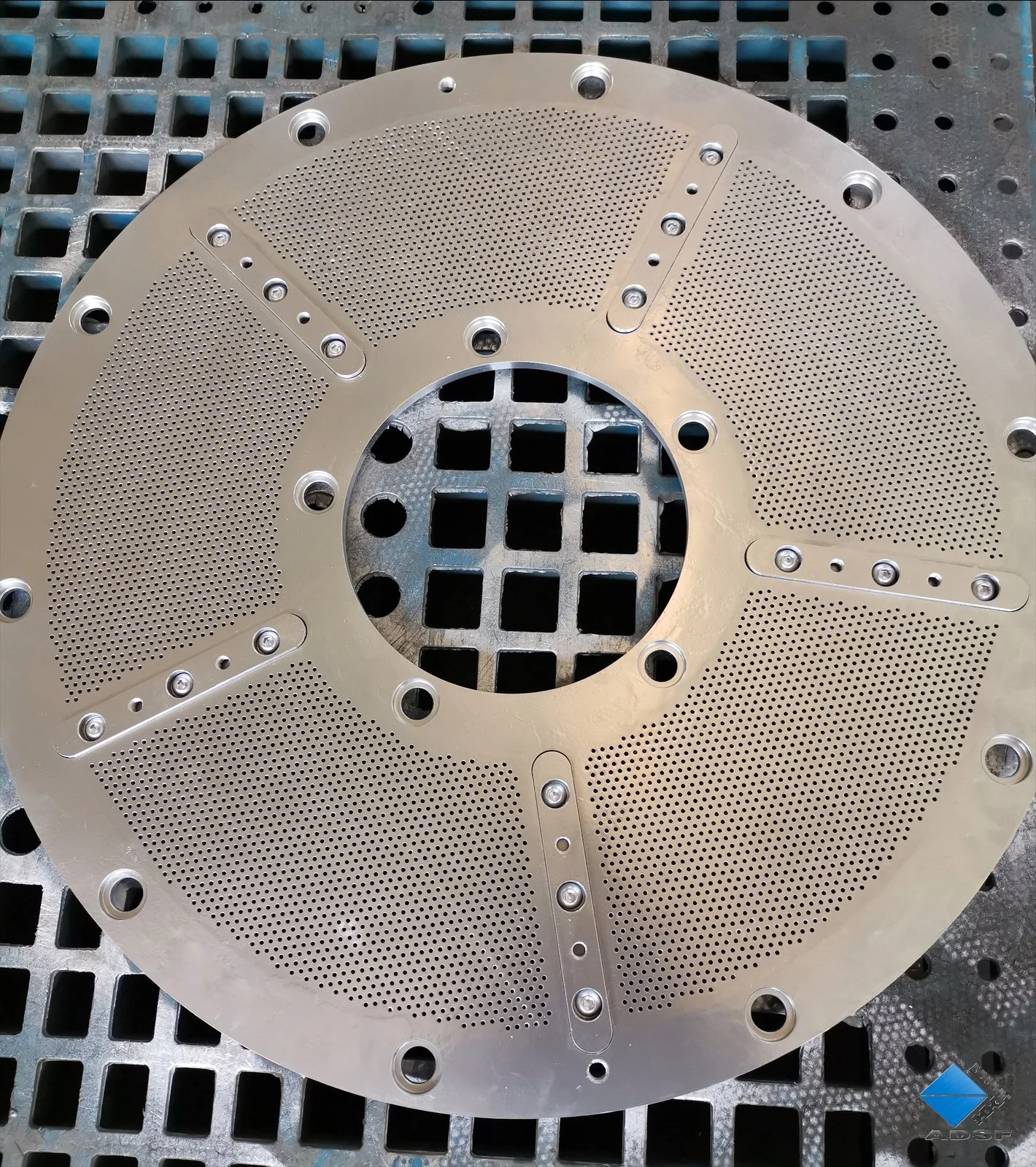

ADSF Drilled Hole Screen Basket manufactured by digital multiple axis drilling system

ADSF Drilled Hole Screen Basket manufactured by digital multiple axis drilling system and mature coating technology. With the different hole designs, our products can achieve higher open area, optimized screening capacity and extended service life

As an ISO 9001 certified manufacturer, ADSF screens meet industry standards and exceed customer expectation.

ADSF products have been passed ISO 9001 over 15 years, we abide by the strict quality standard ensure high quality of products and prompt delivery. With innovative technology, various jigs, advanced equipment, strict QC system, professional talents, we offer quality products to meet customers’ requirement.

ADSF provides a wide range of screen cylinder for meeting client needs

ADSF provides custom designs with various profile types, hole/wire types and open areas available for all applications and process requirement. ADSF drilled hole screen basket has advantages on the low energy consumption, high output and long life time.

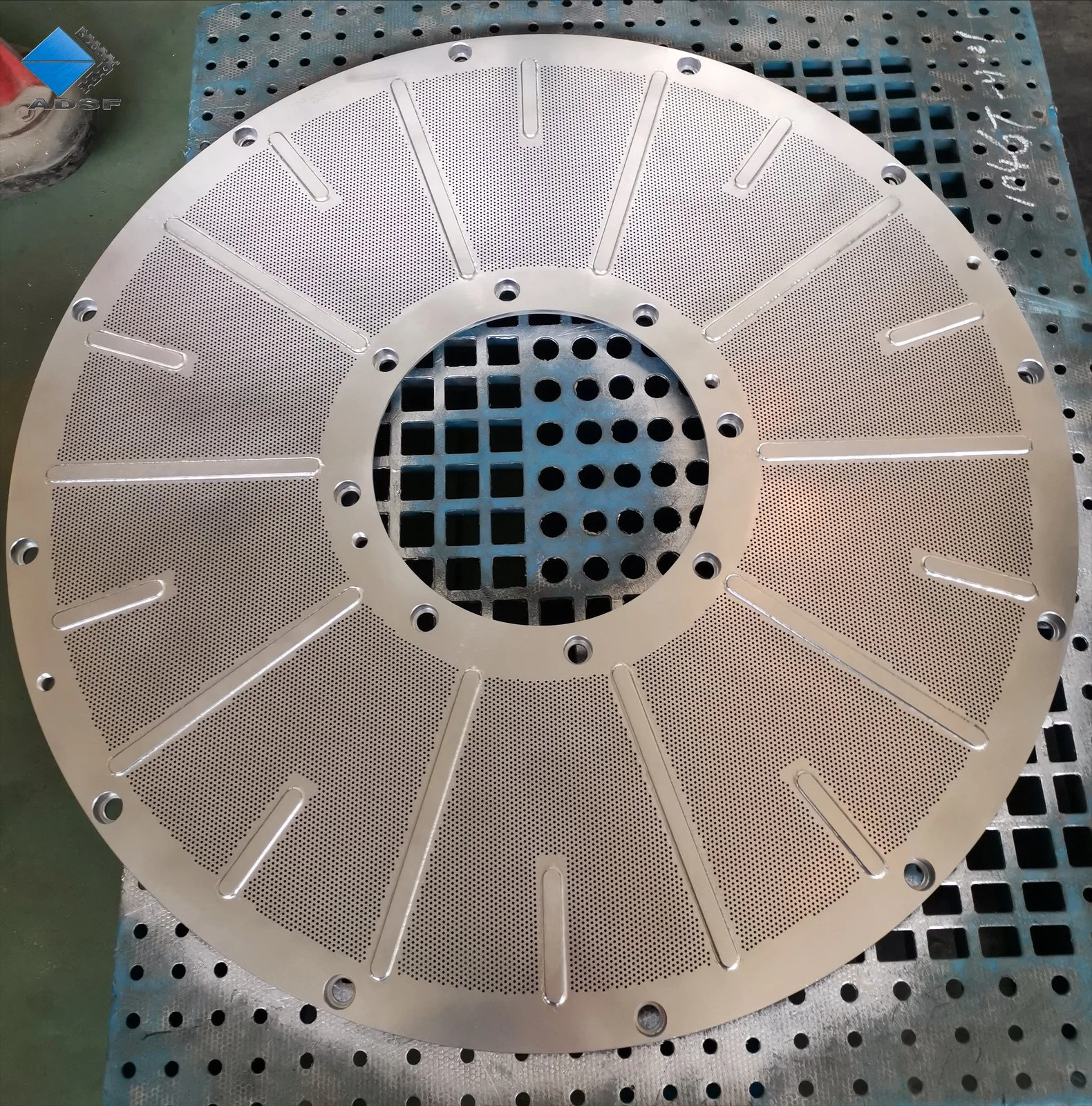

ADSF extraction screen plate adopts various mode of processing

ADSF pulper screen plate works efficiently to separate the contaminants from pulp. The screen holes are arranged in a continuous isosceles triangle to meet the most stringent requirement for paper stock quality and operating performance.

ADSF manufactures high quality screening equipments to fit all process positions

ADSF has professional technical team to offer custom design services and technical advises. All process completed in ourselves facilities, no outsourcing. Our products have the advantages high efficiency, stable performance, long service life and low energy cost. With 37 years, ADSF offers superior, cost-effective and reliable products to reach customers’ requirement.

ADSF pressure screen basket offers various custom designs for all applications and process requirement

ADSF pressure screen basket has advantages on the low energy consumption, high output and long life time. Dynamic Balance Test is provided for each drum rotate cylinder. Dynamic seal can be provided based on customer requirement.

ADSF pulper screen plate is competent on high requirement of production

ADSF pulper screen plate is competent on high requirement for the service life and efficiency of production. The flatness tolerance ≤1.5 With years of experience designing and manufacturing, we provide all variations of extraction screen plates for meeting customer’s need.

ADSF drilled hole screen basket offers various custom designs for all applications and process requirement

ADSF drilled hole screen basket, we provide custom designs with various profile types, hole types and open areas available for all applications and process requirement. Additionally, we offer hard-chrome process for wear resistance quality which increases screens life.

ADSF offers various screen cylinders/plates for all applications and process requirement

ADSF has professional technical team to offer custom design services and technical advises. All process completed in ourselves facilities, no outsourcing. Our products have the advantages high efficiency, stable performance, long service life and low energy cost. With 37 years, ADSF offers superior, cost-effective and reliable products to reach customers’ requirement.

ADSF provides a wide range of screen cylinder for meeting client needs

ADSF Low-concentration compressor screen cylinder. We offer custom designs for all applications and process requirement. ADSF drilled hole screen basket has advantages on the low energy consumption, high output and long life time.

ADSF extraction screen plate adopts various mode of processing

ADSF pulper screen plate works efficiently to separate the contaminants from pulp. The screen holes are arranged in a continuous isosceles triangle to meet the most stringent requirement for paper stock quality and operating performance.

ADSF manufactures high quality screening equipments to fit all process positions

ADSF pressure wedge wire screen basket with water injection holes. The water injection hole is used to inject water into the basket at any time to dilute the pulp consistency. The design of profile wire type conducts the strong extrusion pulping effect which offers higher production rate compared with the naturally pulping.

ADSF pulper screen plate is competent on high requirement of production

ADSF pulper screen plate is competent on high requirement for the service life and efficiency of production. The flatness tolerance ≤1.5 With years of experience designing and manufacturing, we provide all variations of extraction screen plates for meeting customer’s need.

ADSF pressure knotter screen basket (large model)

ADSF pressure knotter screen basket apply for remove the uncooked knag, straw stalks, etc. from cooked pulp. It has the advantages of uniform aperture, low energy consumption and high capacity.

ADSF UV400 coarse screen basket with inside bars

ADSF provides custom designs with various profile types, hole types and open areas available for all applications and process requirement. ADSF drilled hole screen basket has advantages on the low energy consumption, high output and long life time.

ADSF extraction screen plate adopts various mode of processing

ADSF pulper screen plate is competent on high requirement for the service life and efficiency of production. The screen holes are arranged in a continuous isosceles triangle to meet the most stringent requirement for paper stock quality and operating performance. We are dedicated to provide cost-effective and quality screen products for meeting customer needs.

ADSF offers replacement filter for screw press screen to fit customer’s production need.

ADSF Screw Press Screen Cylinder is mainly used for dewatering of pulp and recycled fiber application. It can separate impurities and defiberize stock, regularly improve the productive efficiency, and reduce energy consumption.